Advantages of Welding Over Bolting

Supports should be designed such as after welding actual stress should not be more than allowable stress. Slip-On Flanges are probably the most common type of flanges in the industry and ideal for lower pressure applications.

The Advantages Of Bolts And Nuts Over Welds

Pintle hitches have a clear advantage over traditional ball hitches also called ball mounts when it comes to towing capacity.

. D If fabrication is accurate it is easy to maintain plumb-ness of the frame. Welding is generally a. Threaded Flanges are used for special circumstances with their main advantage being that they can be attached to the pipe without welding.

Can be reused on several projects. Automobiles are made up of thousands of parts and these parts must be manufactured and assembled to form the vehicles frame. Joints are less apt to.

Buttweld fittings can withstand pressures and temperatures in very harsh environments. They are generally considered to be the most robust welding fixture no matter what industry is using them. Naturally joints intended for the two approaches would differ tremendously.

High Capacity Tanks-Bolted Tanks with a roof diameter greater than 29 ft 8 58 in. Medium Capacity Tanks Bolted tanks with a roof diameter of 29 ft 8 58 in. On the other hand many pintle hitches have more than double this weight capacity.

THREADED FLANGE Threaded flanges are joined to pipes by screwing the pipe which has a male thread generally NPT per ASME B1201 onto the flange without seam welds in certain cases though small welds are applied to increase the strength of the connection. The plane of Pipe and support should be parallel all over the piping network to maintain an equal level at each point except for slope lines. Advantages of Buttweld Fittings.

With stick welding and the. Welding is a fabrication process that joins materials usually metals or thermoplastics by using high heat to melt the parts together and allowing them to cool causing fusionWelding is distinct from lower temperature techniques such as brazing and soldering which do not melt the base metal parent metal. Grating Fasteners also known as Grating Clips and G-Clips are simple fasteners that allow bar grating to be attached to steel structures without the need for drilling or welding.

B All welding is done in the shop eliminating problems associated with field welding. Stick welding offers great manual control of the heat that goes into the metals. Threaded flanges are available in sizes up to 4 inches and multiple pressure ratings however.

Stick welding has many advantages that make it overall the best process to weld cast iron to steel. Bolting is a standard fastening method for instance but welding may cut down the weight of assemblies. Long service life above or below water with modest protection.

Grating fasteners are safer because they dont require dangerous welding or drilling. However all joint patterns must consider features such as load factors assembly effectiveness operating surroundings overhaul and upkeep and the materials chosen. This has been the process to build a car for over 50 years.

This is also perfect. Easy to adapt the pile length by either welding or bolting 6. Traditional Class V trailer hitch receivers have tongue weight TW capacities up to 4000 lbs and gross trailer weight GTW capacities up to 25000 lbs.

The principal advantages are. A The connection is suitable for winter erection in that only field bolting is required. The insulation can be placed within the thickness of the steel cold frame or outside of the steel framing warm frame.

Dimension of welded support should be designed with consideration of insulation thickness. Facings and insulation materials such as gypsum board stone wool oriented strand brands OSB and expanded polystyrene foams EPS are added. This has traditionally been done by employees or even robots assembling a conglomeration of pieces think castings rivets welding bolting bonding etc.

Coating the panel with a heat-absorbing compound and stitch welding welding short segments slowly the panel are two ways to keep the panel from warping while being welded in place. Rapid single-pass tap screw assembly of bridging members Standard hand tool fastening for speed convenience and economy Joist spans up to 60 feet reduce bridging counts Enhanced safety using fewer parts no bolting or welding Bridging goes in more quickly safely and economically using a single-pass tap screw instead of drilling. Low 1000-bbl 2000-bbl and 3000-bbl capacity that furnished with a structural- or pole-type center support including a rafter support ring.

It has a variety of welding rods designed to weld cast iron to steel. However they do take a considerable time to fit and a highly skilled installer is needed who can weld them correctly. C Without the need for field welding the erection process is relatively fast and generally inexpensive.

They are assembled by welding bolting or other fastening methods. Provides high resistance to driving stresses. There are many advantages to using grating fasteners.

All cast-iron filler metals are costly but you can buy a small 1 lb 450gr package of stick rods. In addition to melting the base metal a filler material is typically added. This flange is used to seal the end of pipes systems.

5000-bbl and 10000-bbl capacity that furnished with pole-type center support. Steel sheet piling is the most common because of several advantages over other materials.

Bolted Steel Structures After Fabrication Hot Dip Galvanizing Manual

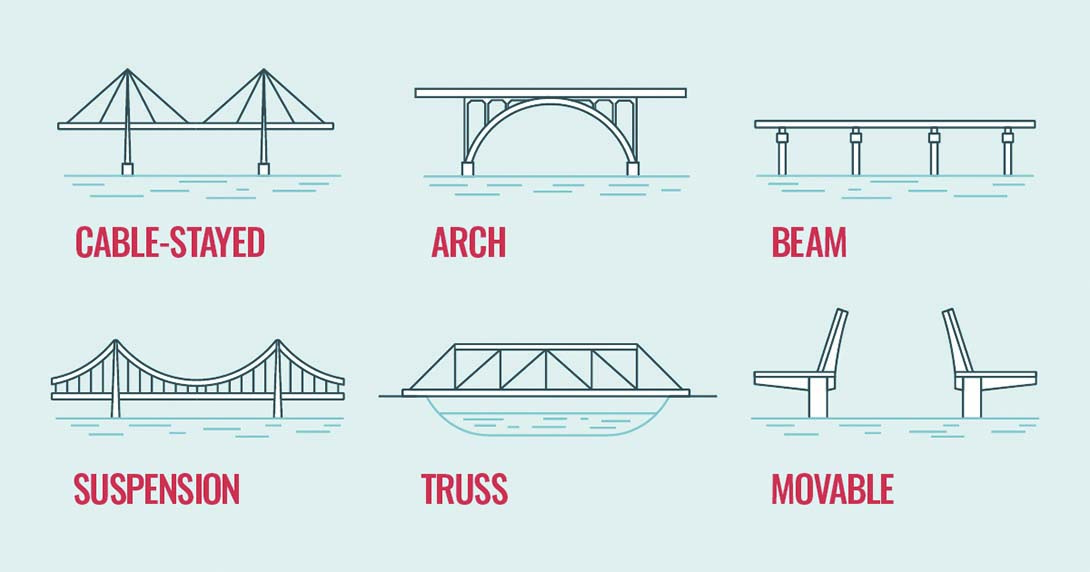

Welding Or Bolting Comparing Joining Methods In Bridge Construction Fastener Fixing Magazine

Comments

Post a Comment